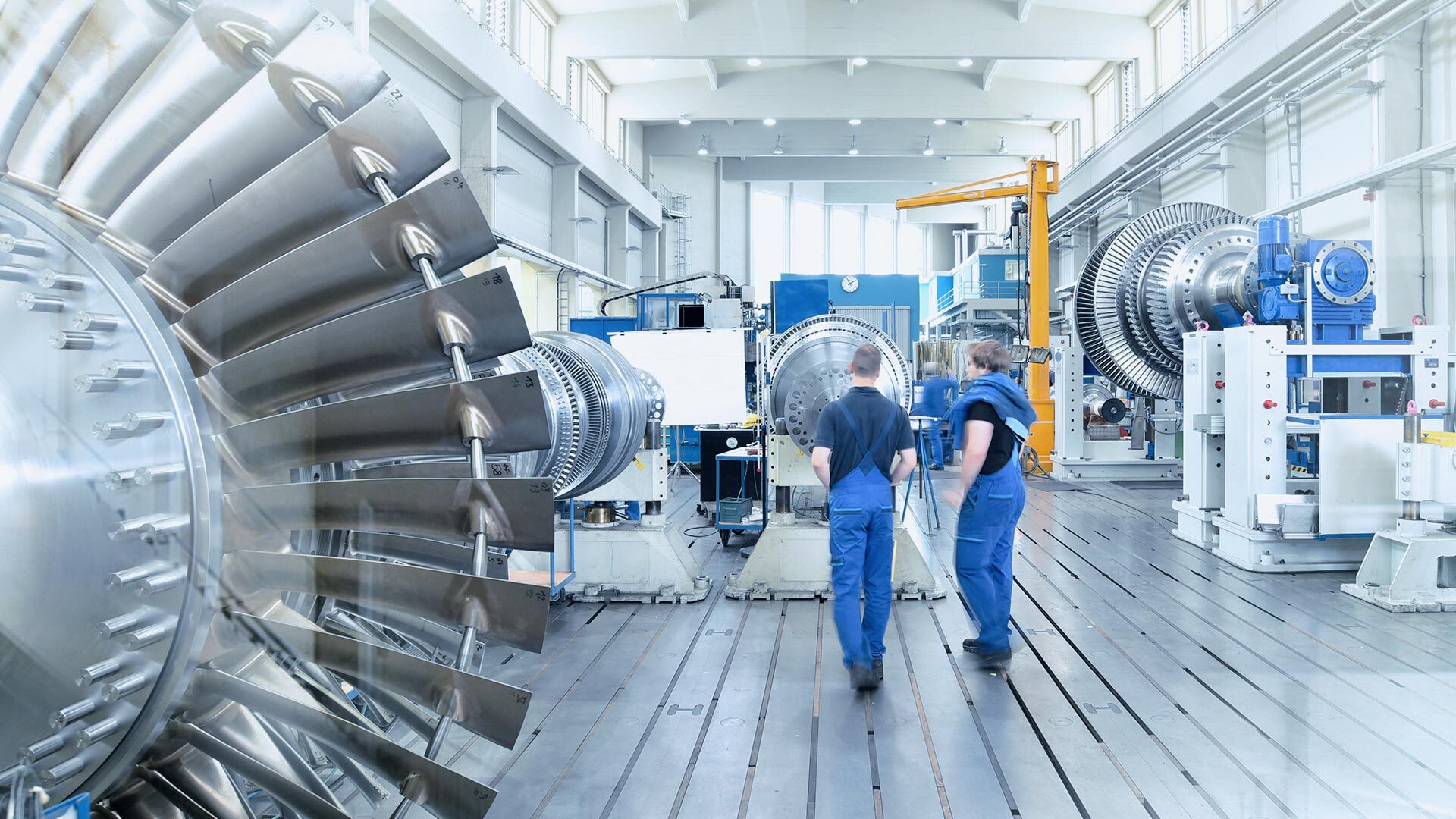

The question of the future has always revolved around new technologies – and what they mean for us. This also applies to mechanical engineering, for which digitization and the advancing (wireless) networking of machines and plants represent challenges and opportunities in equal measure.

By equipping plants with wireless technologies, machine builders who want to bring their products to market are faced with new regulatory requirements. On the other side are users of networked systems whose efficiency gains in production depend on the functionality and performance of the machinery.

Regulatory requirements and performance in use. This is a broad field in mechanical engineering in which we support our customers with consulting and services related to mechanical engineering testing or certification in machine construction.

For the approval of machines and systems, the Machinery Directive is decisive. This directive primarily includes specifications that relate in particular to machine safety in relation to the operator.

With the advancing digitalization and the associated networking of devices, machines and production sites, the specifications for the approval of devices or certification in mechanical engineering are changing significantly. A wide variety of challenges arise for the performance and reliable and safe operation of the digitized and networked machines and systems in use.

cetecom advanced and our wholly owned subsidiary cesitec offer a portfolio of services tailored to the challenges associated with the approval and use of machinery and equipment. This makes cesitec and cetecom advanced ideal partners for companies in this segment.

cesitec is an active service provider in mechanical and plant engineering for the areas of machine safety, occupational safety and functional safety.

cesitec supports the industry with qualified engineering services and helps to optimize CE processes in the company. The range of services includes the preparation of verification documentation, engineering and consulting with regard to safety technology and support in all phases of project execution. The focus is on finding legally compliant and economically viable solutions for customers.

With the changing requirement to equip plants with wireless technologies, machine builders who want to bring their products to market are facing new regulatory requirements. On the other side are users of networked plants, whose efficiency gains in production depend on the functionality and performance of the machinery. This is where cetecom advanced comes into play: Regulatory requirements and performance in use. A broad field in mechanical engineering in which we support our customers in word and deed.

Even the use of a single radio module (e.g. Bluetooth, WLAN or 2G/3G/LTE/5G) means that the Radio Equipment Directive 2014/53/EU must also be used for CE marking.

The Radio Equipment Directive (RED) 2014/53/EU has been mandatory since June 13, 2017 for all radio equipment that falls within the scope of this directive. The directive has completely replaced the R&TTE directive after a transitional phase as of this date.

The scope of application addressed relates to all devices and machines that use a radio module, regardless of whether (previously) other specifications and directives are (or were) used, e.g. the Machinery Directive.

The technologies used determine the test framework, which is defined in the Radio Equipment Directive:

Provided that the underlying standards are harmonized, manufacturers have the option of drawing up a self-declaration (EU declaration of conformity). The involvement of a Notified Body Radio is therefore optional.

If a Notified Body is involved, it will issue an EU Type Examination Certificate for the manufacturer after examining all test reports and reviewing the submitted documents. This often facilitates the certification process for international market approvals.

Security, data throughput, availability: characteristics that are inseparable from an efficient production facility.

With more than 25 years of experience in connectivity and wireless networking, combined with our expertise in mechanical engineering certification and testing, we are your ideal partner for networking your production facilities:

Are you looking for legally compliant and economically viable solutions for machine safety and occupational health and safety?

Do you need support in networking your production sites?

We are at your side – competent, efficient and at eye level with our customers.

You would like to exchange ideas with us? Get in touch with us now:

mail@cetecomadvanced.com / +49 2054 9519 0

info@cesitec.de / +49 209 15519-100